Long Life Earth Electrode Patent Pending

Long Life Earth Electrode Patent Pending

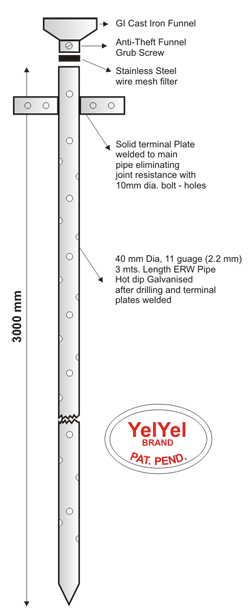

YEL YEL' brand earth earth electrodes are manufactured from right size 11 guage (2.2mm), 40mm dia, 3 mts. length pipe. After the holes are drilled and terminal plates welded, the whole unit is hot dip galvanized. This process will not leave any exposed iron surfaces, resulting in long life of earth electrode. The dimension conforms to IS 3043.

The terminal plates at the two sides are with two holes to take 10mm dia. GI bolts on either side (four bolts with eight washers and four spring washers are supplied). A detachable cast iron GI funned with stainless steel wire mesh is screwed at the top. Anti-theft funnel grub screw is provided. The special terminal arrangement gives better performance of the electrode, than the method suggested by IS specifications. As per IS this pipe electrode could be used in place of 100 mm dia. cast iron pipe or a plate electrode. The area of wall thickness of 2.9mm and 40mm dia pipe is 365 Sq. mm. As per table 6 of IS 3043, this area can withstand a current of 29,000 amps for one second. Hence, is suitable for use in power substations, distributions sub-stations, medium voltage and low voltage installations.

Earth electrode can transmit earth fault currents to earth mass for only a very short duration to trip earth fault relays. If earth fault current persists for longer time. Surrounding earth gets heated, the ground resistance will increase and the purpose is defeated.

As per Indian Electricity Rules, for electrical equipments, one earth electrode shall be provided for voltage upto 240V and two earth electrodes for voltages above 240V.

Extensive trials with YEL YEL brand earth electrodes were conducted by Electricity Board and the performance was found to be excellent.

Method of Installation

With and earth auger of size 225mm or 150mm make a 3000mm hole in the earth. Insert the earth electrode. Fill the surrounding space with a mixture of salt, charcoal and earth. Tightly ram the mixture. Pour water into the funnel, allow the water to percolate into the earth. Test for earth resistance values. This test should be conducted when the surrounding earth is dry. Construct a masonary trough of size 375 x 375 x 375mm leaving holes at the bottom of four side wall for incoming earthing conductors. Connect the leads after testing for earth resistance values.

In plains a value of less than 1 Ohm could be achieved, if not, treat the surrounding soil with common salt of magnesium sulphate. if still the required values are not achieved install more number of earth electrodes and connect them in parallel. If rock is encountered, install the electrodes and connect them in parallel. If rock is encountered, install the electrode at 30 degree inclination to ground. Low resistance values could be achieved only by installing the electrodes by earth auger, then by digging a large pit with a loose fill.

Install earth electrodes in open ground at 1500mm away from walls nd with a space of not less than 3000mm between two earth electrodes. For ease of installation do not cut the pipe. Do not drive the pipe into earth by hammering on the funnel. This will damage the funnel and pipe.

Earth Pipe

Dimention : Dia 40mm x 11 guage (2.2 mm)

Length : 3 mts.

Weight : 9.5 Kgs. (Approx.)

Code : 1009